Published

Last 1 week

Last 30 days

Latest 24 hours

Profession

Industry

Energy, utilities, environment jobs

Human resources, talent development, recruiting jobs

Raw materials, oil, chemicals jobs

Seniority

Published

Profession

Industry

Seniority

3

jobs

Fadac Resources and Services

Portharcourt, Nigeria

Fadac Resources and Services

Portharcourt, Nigeria

SPIE Oil & Gas Services

Portharcourt, Nigeria

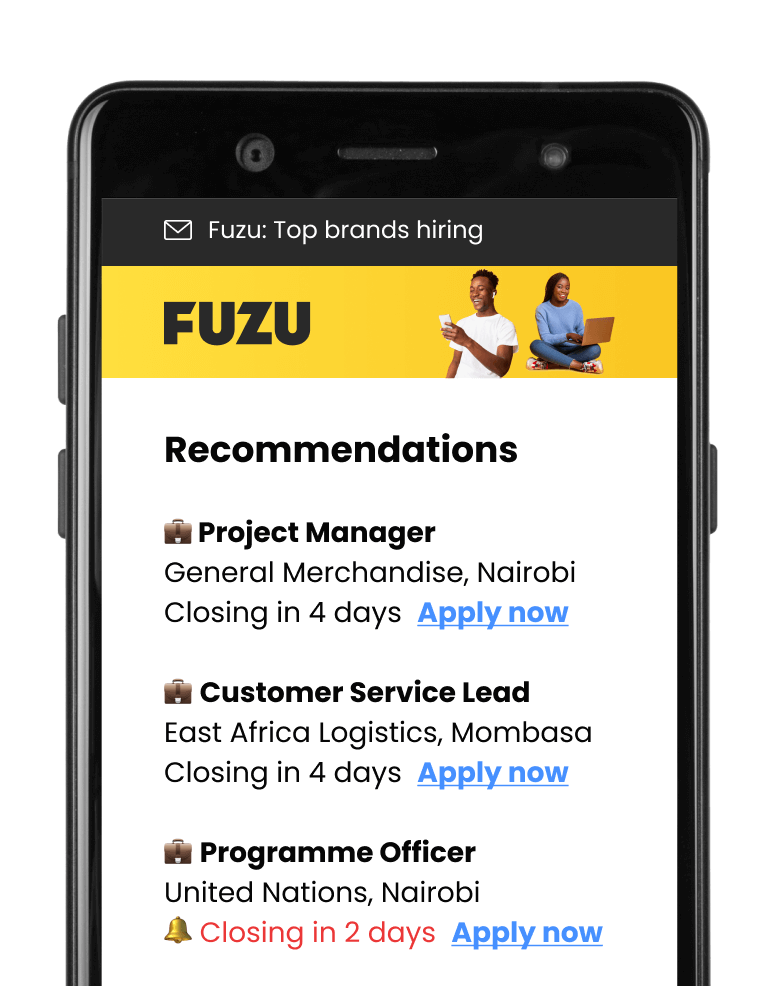

Get personalised job alerts directly to your inbox!

WTS Energy

CLOSEDPortharcourt, Nigeria

Closing: May 25, 2024

8 days remainingPublished: May 16, 2024 (1 day ago)

Education:

Work experience:

Language skills:

Contract Type:

Sign up to view job details.

How to Apply

Interested and qualified candidates should send their CV to: the provided email address using the Job Title as the subject of the mail.

How to Apply

Interested and qualified candidates should send their CV to: the provided email address using the Job Title as the subject of the mail.

Applications submitted via Fuzu have 32% higher chance of getting shortlisted.