Closing: Jul 12, 2024

6 days remainingPublished: Jul 2, 2024 (5 days ago)

Job Requirements

Education:

Work experience:

Language skills:

Job Summary

Contract Type:

Sign up to view job details.

- HND/B.Eng or equivalent in Mechanical or Electrical/Electronic Engineering

- Minimum of 3-5 years as Process Artisans or Maintenance Artisan on high-speed packing lines

- Computer Literate

- Systemic and Analytical problem-solver

- Good leadership potential

- Good understanding of modern maintenance practices and maintenance system, and production processes and technologies

- Influencing ability with regards to sound maintenance

Responsibilities

- HND/B.Eng or equivalent in Mechanical or Electrical/Electronic Engineering

- Minimum of 3-5 years as Process Artisans or Maintenance Artisan on high-speed packing lines

- Computer Literate

- Systemic and Analytical problem-solver

- Good leadership potential

- Good understanding of modern maintenance practices and maintenance system, and production processes and technologies

- Influencing ability with regards to sound maintenance

- The key purpose of this role is to maintain, calibrate, repair equipment, optimise Packaging equipment and associated devices to ensure availability and product quality.

Key outputs and responsibilities

Operational Support:

- Provide specialist support for coaching, mentoring and knowledge transfer of machine operation to shift based teams

- This will include standby, day shift and when requested after a time frame that standby will need expert advice or support

- Where requested, assist as a functional expert in problem solving for the plant and support to zone

- Take part, as functional expert, in regional and central office plant optimization trials

- Provide additional support to process artisan on machine operation, machine fault finding and correct responses to machine failure modes

- Upskill process artisans with latest SWI for machine setups or machine restorations

Planned Maintenance:

- Take part in maintenance planning meeting, contributing suggestions and clarifying work required

- Ensure backlog meets minimum hours and schedules are reviewed as per required frequency

- Carry out work during the planned maintenance window in accordance with the planned maintenance schedule issued by the planner

- Assist fellow team members in the execution of their tasks in during planned maintenance windows

- Partake in maintenance postmortems to feedback problems, opportunities and learnings from maintenance activities

Routine Maintenance:

- Partake in ATO cleaning, lubrication and inspection in accordance with the maintenance schedule issued by the Maintenance Planner must be resolved using the appropriate problem-solving techniques

- If Carry out routine maintenance activities in accordance with the maintenance schedule where problems have been uncovered during routine maintenance, these required, additional resources may be called in to assist

- Where problems have been uncovered, and it is required to include the work in the planned maintenance schedule, this must be communicated to the Maintenance Planner

- Carry out condition monitoring activities where these have been allocated to the Technician in accordance with the ZCM schedule

Problem Solving:

- Where problems have occurred during routine activities, apply the correct problem-solving approach to resolve

- Assist fellow team members to resolve problems on request take part, as functional expert, in AB- Report , SDCA and PDCA on request

Housekeeping and Safety:

- Always operate in a safe manner, and identify and highlight unsafe work practices so that these may be corrected

- Carry out work according to the work instructions and adhere to appropriate AB-Inbev policies and procedures

- Carry out housekeeping tasks, and apply 5S principles during the execution of duties

- Present 5’s plans to team and management when required

- Raise and close SIO’s related to your machine area

Running Repairs:

- On request, partake in carrying out running repairs on plant and equipment, or support the Shift Artisans in carrying out repairs

- When carrying out repairs, assess the problem and determine a course of action. Where required, specialist assistance may be called in

- This may include internal resources such as Instrument

- Technicians or Inspection and coding specialist or external resources such as Contractors or Suppliers

- Where repairs indicate that major work is required, such as re-wiring a motor, this must be transferred to the engineering workshop for attention

- Verify that where running repairs have been carried out, this has addressed the problem

- Complete the administration tasks relating to any running repairs that the Technician has carried out

- This includes all SAP inputs

- Where running repairs cannot be carried out, communicate this to the Maintenance Planner to ensure the work is planned into the next

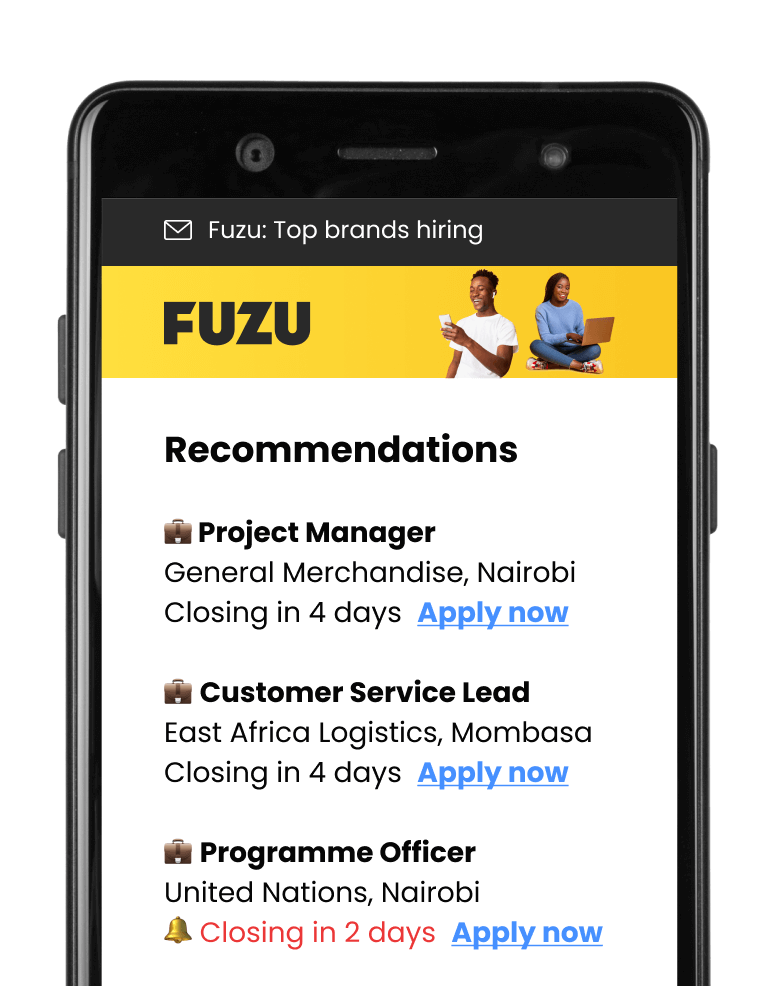

Applications submitted via Fuzu have 32% higher chance of getting shortlisted.