Published

Profession

Industry

Seniority

Published

Profession

Industry

Seniority

2

jobs

International Breweries Plc

Onitsha, Nigeria

International Breweries Plc

Onitsha, Nigeria

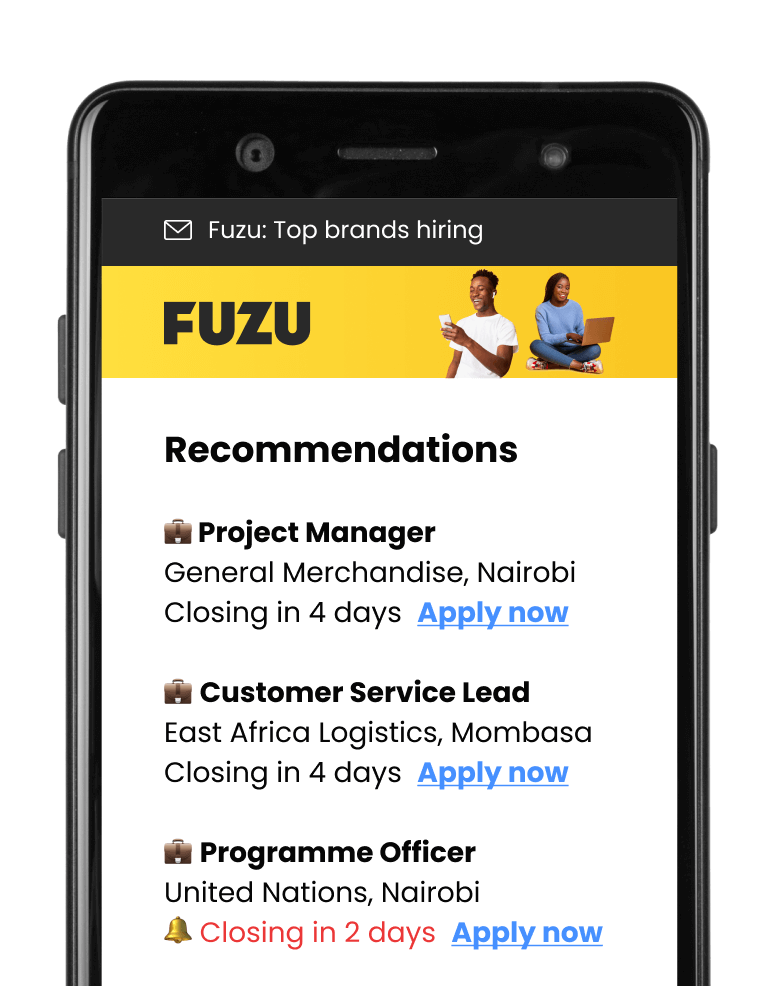

Get personalised job alerts directly to your inbox!

International Breweries Plc

CLOSEDOnitsha, Nigeria

Closing: Jul 12, 2024

6 days remainingPublished: Jul 2, 2024 (5 days ago)

Education:

Work experience:

Language skills:

Contract Type:

Sign up to view job details.

Key outputs and responsibilities

Operational Support:

Planned Maintenance:

Routine Maintenance:

Problem Solving:

Housekeeping and Safety:

Running Repairs:

Applications submitted via Fuzu have 32% higher chance of getting shortlisted.