Published

Last 1 week

Last 30 days

Latest 24 hours

Profession

Industry

Energy, utilities, environment jobs

Governmental jobs

Non-profit, social work jobs

Telecommunications jobs

Seniority

Published

Profession

Industry

Seniority

3

jobs

TotalEnergies

Kampala, Uganda

The Food and Agriculture Organization

Kampala, Uganda

IHS Towers

Lagos, Nigeria

TotalEnergies

CLOSEDKampala, Uganda

County of Nairobi

CLOSEDNairobi, Kenya

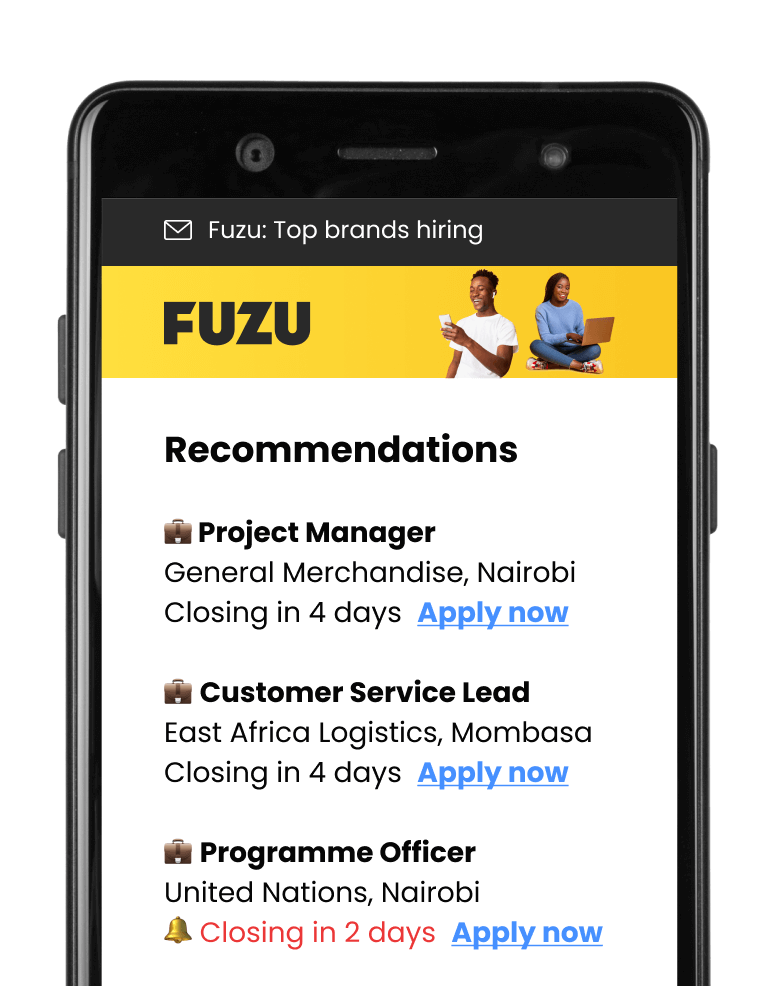

Get personalised job alerts directly to your inbox!

IHS Towers

CLOSEDLagos, Nigeria

Closing: Jul 28, 2024

22 days remainingPublished: Jun 18, 2024 (19 days ago)

Education:

Work experience:

Language skills:

Contract Type:

Sign up to view job details.

Requirements

• Engineering degrees in Mechanical, Metallurgy and/or Chemical,

• Minimum 10 years in oil and gas business, particularly in inspection.

• Minimum 6 years in multi-discipline inspection works.

• High level of knowledge in NDT, welding inspection, preferably complimented by the possession of NDT certifications.

• High level of knowledge in inspection method and techniques, and international codes and standards for oil and gas industry. Good knowledge in inspection working management systems: SAP, RBI and other relevant systems.

• Good knowledge of corrosion and process equipment failure modes.

• Mastery in inspection method and techniques, with strong experience in NDT, inspection method and techniques, and international codes and standards for oil and gas industry.

• Good leadership, communication, close coordination and active team player with other team members in the department. Very good knowledge in corrosion and process equipment failure modes and of international and COMPANY inspection references, codes and standards.

• High level of knowledge of static mechanical equipment: Pressure Vessel, Heat Exchanger, Piping and Pipeline, Lifting equipment international inspection codes and standards.

Requirements

• Engineering degrees in Mechanical, Metallurgy and/or Chemical,

• Minimum 10 years in oil and gas business, particularly in inspection.

• Minimum 6 years in multi-discipline inspection works.

• High level of knowledge in NDT, welding inspection, preferably complimented by the possession of NDT certifications.

• High level of knowledge in inspection method and techniques, and international codes and standards for oil and gas industry. Good knowledge in inspection working management systems: SAP, RBI and other relevant systems.

• Good knowledge of corrosion and process equipment failure modes.

• Mastery in inspection method and techniques, with strong experience in NDT, inspection method and techniques, and international codes and standards for oil and gas industry.

• Good leadership, communication, close coordination and active team player with other team members in the department. Very good knowledge in corrosion and process equipment failure modes and of international and COMPANY inspection references, codes and standards.

• High level of knowledge of static mechanical equipment: Pressure Vessel, Heat Exchanger, Piping and Pipeline, Lifting equipment international inspection codes and standards.

• Establish site inspection activities plan in close coordination with other relevant entities: production, safety, maintenance.

• Participate to the Baseline Inspection development and dossier preparation by MIEC

• Support the start-up and deployment of the Inspection Services Contractor to site and follow deployment of NDT operators for Baseline

• Work with Site construction team and commissioning team to plan and execute the baseline inspection against the defined requirements

• Implementation and Training on Inspection Operation Tool and responsible for its follow-up on site.

• Commence the preparation of the site special tools requirements and pilot procurement with C&P team

• Support UPIK training of new inspectors for site.

• Implement site Lifting Inspection Management system with Logs and CPLO

• Work safely, avoid any incident and dangerous situation, contribute towards continual HSE improvement, demonstrate safety behavior.

• Attend mandatory HSE trainings and apply them on site, ensure team and vendor compliance

• Support to maintain and continually improve ISO 14001 Environment Management System requirements and other management initiatives.

• Ensure the safe operation and adherence of all site inspection activities to their planned schedule

• Perform and supervise site inspection activities to ensure their adherence to the defined scope, method, procedures and the applicable relevant codes and standards.

• Plan, prepare, coordinate, and supervise inspection activities performed by third-party contractors to ensure that work is performed in accordance with procedure

• Witness and follow-up the Pressure Safety Device certification and update their status in the system as required in close coordination with maintenance & production teams.

• Alert management through the hierarchy on any critical inspection findings giving a threat to asset integrity, and prepare the detail report in order to facilitate the hierarchy to analyze the situation and taking a good proper decision,

• Complete CMIMS required processes for all site inspection activities,

• Initiate, discuss and up-date inspection procedures, method and plan in close coordination with relevant parties.

• Review any ad-hoc inspection requests/notifications to establish the scope, method and procedure requirement including their integration into the existing site inspection planning in coordination with the relevant parties,

• Contribute on any equipment failure analysis, by aiding in performing the necessary inspection to collect information required for the analysis by other relevant teams.,

• In coordination with relevant parties, establish the shut-down inspection scope and planning. Identify external resources requirement and propose working organization during the shut-down.

• Ensure that Pipeline Integrity Management System (PIMS) and Tank Integrity Management System (TIMS) are in place..

• Provide assistance in performing the QC inspection for modification & repair works.

• Develop the local staffs within the department the field of inspection.

• Maintains facilities, equipment and all other inspection tools in a clean and operational condition.

• Contribute to the inspection budget preparation through identification of any special/campaign.

Applications submitted via Fuzu have 32% higher chance of getting shortlisted.